CLEA Technologies Enzyme Immobilization and Biocatalytic Process Development

CLEA Technologies is an internationally recognized leader in enzyme immobilization and biocatalytic process development. Enzymatic processes often outperform their chemical counterparts in terms of rate, (enantio) selectivity, energy consumption and environmental acceptance. Enzymes are derived from renewable resources and are biocompatible, biodegradable and exquisitely selective catalysts.

Our unique proprietary cross-linked enzyme aggregate (CLEA) immobilization technology dramatically improves the operational stability of enzymes and provides for their facile recovery and reuse. Let us show you that it is not only better to use enzymes, but also how to use enzymes better. Our customers benefit from our broad expertise in biocatalysis and our philosophy of proactively working with the client to find the best solution.

Cross-linked enzyme aggregates in the processing of foods and beverages

From a starting point of a strong customer base in the pharmaceutical and fine chemical industry CLEA Technologies is venturing into new and exciting markets. There are numerous (potential) applications of CLEAs in the processing of foods and beverages, including:

- Lipase CLEAs in the processing of fats and oils, e.g. in the production of omega-3 ingredients for use in functional foods, beverages and nutritional supplements

- Phospholipases in refinement of vegetable oils

- Protease CLEAs in the processing of, for example, milk proteins

- Lactase CLEAs in the removal of lactose from milk and the production of galacto oligosaccharides (GOS) for use as prebiotics in nutritional supplements

- Pectinase combi CLEAs in fruit juice manufacture

- Glucose oxidase / catalase combi CLEAs in removal of glucose from egg-white and oxygen from fruit juice

- Phytase CLEAs in novel nutritional applications

- Laccase CLEAs in wine and beer clarification

These are just a few examples of the boundless possibilities offered by CLEAs.

Immobilized enzymes for food processing

Hydrolysis and trans-esterification of triglycerides are textbook examples of reactions that are catalyzed by a variety of lipase enzymes. The enzymatic processes have advantages over the conventional chemical process in that they proceed under milder conditions and may require less costly equipment. Moreover they produce fewer by-products so that there is less waste, simpler, less expensive downstream processing and they afford a higher quality product. However, the major benefit of using a lipase is the added control over the nature of the product as a consequence of the specificity naturally shown by many lipases.

The added benefits of using immobilized enzymes are significantly improved thermal stabilities, which facilitate processing at higher temperatures under more sterile conditions, shorter reaction times and higher throughputs. We offer a highly relevant selection of lipase CLEA and their non-immobilized counterparts in our lipase discovery platforms.

It is important to note that our methodology for immobilization of enzymes produces food-grade ingredients in accordance with 21CFR173.357 Sec. 184.1372.

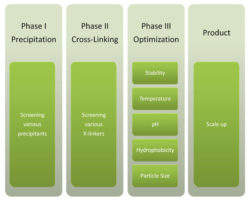

Enzyme immobilization services

We offer two types of enzyme immobilization service:

- Off-the-shelf CLEAs of a variety of commercially available enzymes (see our website for a list or please enquire)

- Custom immobilization of enzymes provided by the customer and which can be on an exclusive basis. In this way we can optimize the operational performance of the customer’s enzyme for a particular application. This could be as a CLEA but it could also involve another immobilization technology

Enzyme process development

Our process R&D services will help you to identify more cost-effective alternatives for existing processes as well as innovative and competitive new processes to meet your R&D goals.

Based on our extensive experience in biocatalysis and our broad platform of commercial and experimental enzymes from numerous enzyme manufacturers, we can perform screening studies on your target application, and optimize and scale-up reactions, with guaranteed technology transfer.

Products and Services

Video

Related Projects

Press Release

Regional Offices

Delftechpark 34

2628 XH, Delft

Other

Netherlands