Mindful water management and a decrease of the fresh water intake should be one of the most important commitments of food and beverage manufacturers. In developed countries, more than 50% of the water suitable for human use is consumed by industries; thus, conservation, reuse, and recycling of wastewater are one of the crucial steps on our way to the global circular economy.

Mindful water management and a decrease of the fresh water intake should be one of the most important commitments of food and beverage manufacturers. In developed countries, more than 50% of the water suitable for human use is consumed by industries; thus, conservation, reuse, and recycling of wastewater are one of the crucial steps on our way to the global circular economy.

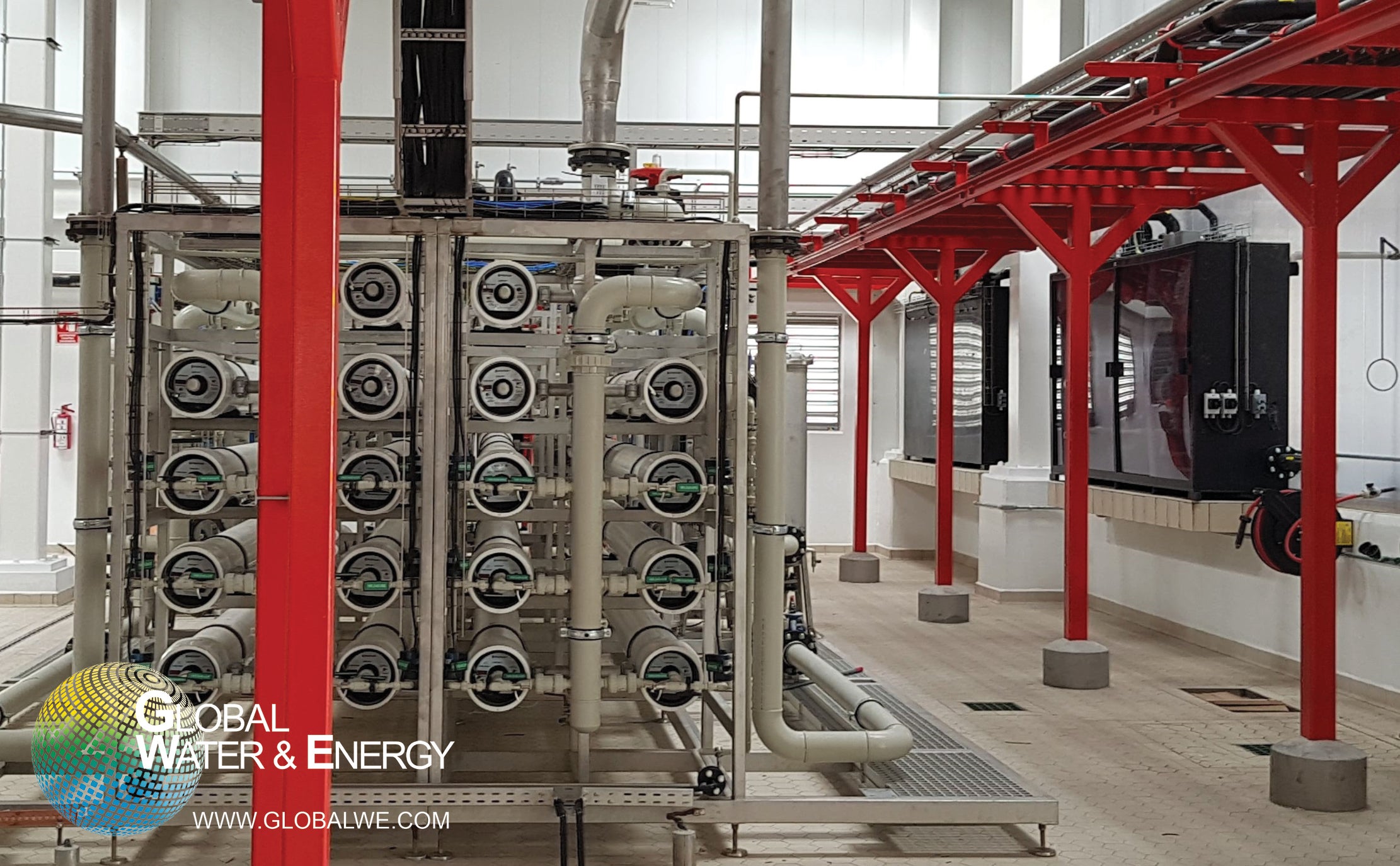

GWE water reuse plants are custom-engineered installations that put in place multi-barrier systems to treat effluent from wastewater treatment plants. The tailor-made water recycling systems combine efficient pre-treatment and the latest membrane separation technologies to obtain high-purity water – guaranteeing a permanent source of water for production and cleaning.

Closing the water loop

The turnkey water reclamation plants from GWE have already been installed at three major breweries, allowing those facilities to reuse about 7000 cubic meters of post-production wastewater daily. In essence, it is more than 2,5 million cubic meters of water saved per year.

The consumption of fresh water for industrial purposes must decrease in the upcoming years. Therefore GWE dedicates its effort to test different proprietary technologies to help their

Reclamation of the wastewater treatment plants’ effluent not only provides a reliable supply of water that can be used for various purposes but also reduced fresh water usage ratios and decreases the water bill.

The necessary unit processes are chosen from the whole range of modern technologies available, for the treated water meets the reuse requirements. With custom solutions, optimised to the client’s needs and local conditions, the capital and operational costs are always at their lowest.