The Austrian company Insort will receive a silver medal at this year’s AnugaFoodTec Award for its development of the Sherlock Separator and associated technology. Sherlock Separator employs state-of-the-art Chemical Imaging Technology to bring recent advances in near-infrared spectroscopic imaging to the food industry – with the aim of bringing an extra dimension of quality assurance to food production.

The precision of laboratory-based analytical techniques using near-infrared spectroscopy is well established and will continue to be of great use to the food industry. With recent advances in the continuous development of Chemical Imaging Technology in the near-infrared, it is now possible to acquire in-line process data of the chemical characteristics of food produce in real-time, at industrial levels of through-put. Many applications, such as monitoring food produce streams for relevant chemical data, inspection for foreign objects or complex grading and sorting of food, can now be implemented in an industrial setting.

Detection of sugarends in the production of French fries

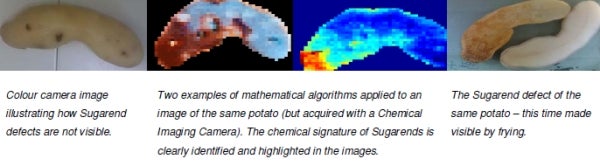

Potato sugarends are the result of the accumulation of reducing sugars at the ends of potatoes. This common defect is invisible to the naked eye when a potato is raw; however, when potatoes are fried it becomes noticeable as an unsightly and unwanted browning of the ends of French fries (due to Maillard reactions). The potato industry only produces partially fried French fries and hence the end customer will be the first to discover the sugarend defect. Insort has developed the Sherlock Separator to be a targeted solution for problems that are relevant to the food industry.

"With this technology it is possible to detect and sort all the fundamental defects associated with potatoes, such as incomplete peeling, green potatoes and spoilt potatoes. Every kind of foreign object, and more specifically any defects that are normally invisible, can be detected and rejected," explains Matthias Jeindl, chief executive of Insort.

Foreign object detection in the fruit processing industry

Chemical Imaging Technology excels at eliminating foreign objects from food production processing because it only requires the near-infrared spectra representing good quality produce to be able to recognise if an object’s infra-red spectrum is dissimilar and hence foreign. It is therefore also possible to scan and classify fruit according to a quality grading. For instance, when spectral features of a scanned fruit lie within the defined chemical boundaries of ‘good quality’, the classification algorithm will colour the fruit’s image pixels green.

Image pixels that contain some chemical signatures that lie outside these defined boundaries will automatically be interpreted as foreign and will correspondingly be coloured red. This enables the Sherlock Separator to easily detect foreign objects – without the requirement that it be taught all possible foreign objects that it may encounter.

Summary

Chemical Imaging Technology is an innovative and exceptionally efficient process for in-line monitoring or sorting of produce streams in the food industry. The camera system delivers spatially resolved, pixel-by-pixel, spectrum analysed images that are highlighted with colour according to our proprietary algorithms. This process delivers a chemical image of an object – with invisible defects made visible – that is easily interpreted. Chemical Imaging Technology is a young technology that delivers innovations to quality assurance control and foreign object detection, and it stands to offer much more in the future.