In the meat rendering industry, tiny and sharp pieces of stainless steel spring wire are commonly found in meat-containing meals containing offal.

Capsule debris from the drenching process can remain in livestock’s stomach at the time of slaughter, which is then ground up by process facility’s mills and grinders, causing metal contamination. If not properly detected and removed, these contaminants can cause considerable damage for the companies involved.

The consequences of metal contamination

Foreign matter contamination can have devastating effects on the companies involved, including:

- Product recalls

- Customer complaints

- Brand name damage

- Equipment damage

- Financial loss

- Harm to pets and livestock

The solution: high-strength RE80 magnetic separators

MAGNATTACK™ Global became involved in the meal industry in 2013 when they were contacted by an Australian rendering processor experiencing serious contamination issues in their final meat meal product. These issues had been identified as very sharp tiny metal fragments, which left the client with a serious need for foreign matter control.

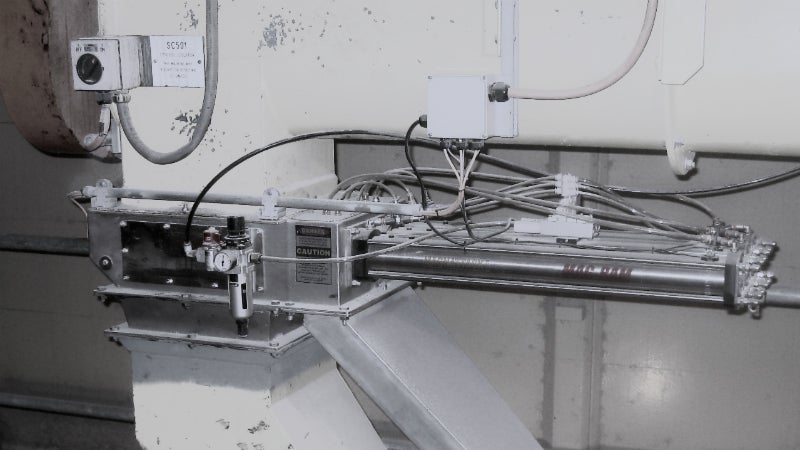

Working closely with the client to assess the risks involved and determine the best magnetic solution to meet requirements and make dramatic improvements to their meal quality, MAGNATTACK™ Global were able to provide an answer to the problem, a specially customised MAG-RAM™ Self-Cleaning Separator.

The now-patented system has been proven through many years of research, trials, and development to ensure maximum extraction of foreign matter and metal contamination. The satisfied client claims the MAG-RAM™ unit provided a positive reduction in risk. Southern Meats’ Scott Newton said it gave "a safer, much cleaner, and more valuable product than before, a highly recommended innovation".

The MAG-RAM™ advantage

Why does the MAG-RAM™ supersede ordinary grate magnets and overcome problems inherent with conventional self-cleaning designs?

- Manufactured with MAGNATTACK’s patented RE80™ High-Strength Elements

- Cuts manual cleaning labour time, as grate magnets are difficult and time consuming to clean and they also require frequent cleaning to maintain efficiency

- Ability to clean one bar at a time instead of entire rows, making in stream cleaning safer and more efficient, as well as reducing risk of metal getting past during a cleaning cycle

- More contact of the product with cleaned magnet surface due to large diameter bars

- Can be installed in difficult-to-access locations, reducing cleaning and operator safety risks. OSHA handling hazards eliminated with safer cleaning procedures, no heavy lifting

- It is fully customisable and the frequency of cleaning parameters can be adjusted according to the level of contamination and throughput

- Certified by HACCP International

- Proven anti-abrasion features

Australian Renderer’s Association Inc.

MAGNATTACK™ Global recently received recognition for the MAG-RAM™ by the Australian Renderer’s Association at the 2015 Symposium held in QLD Australia, for the innovation and success of this system within the industry, and will be showcasing this piece of equipment again at the ARA 2017 Symposium.

This system is now used extensively across Australia, New Zealand, and the US, and is fast becoming a valuable and necessary addition for foreign object control across the meat rendering industry.