WITT offers certified quality systems for leak detection of all types of packaging.

WITT offers certified quality systems for leak detection of all types of packaging.

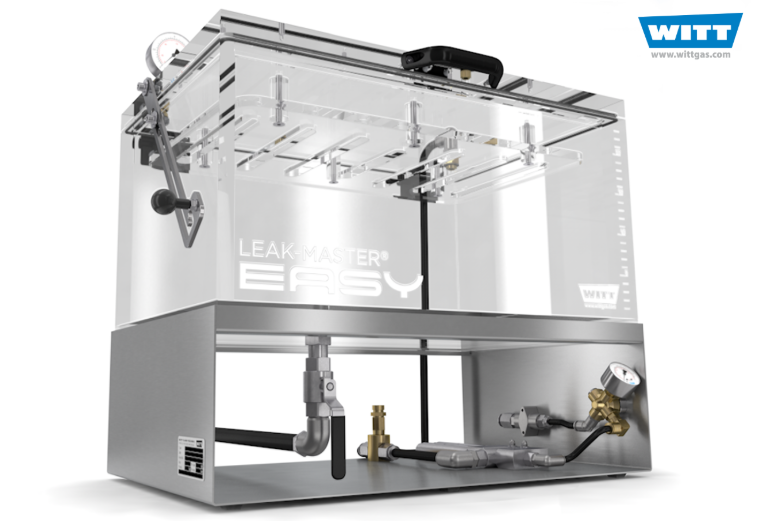

LEAK-MASTER EASY: Bubble-test leak detection

LEAK-MASTER EASY features the detection of even the smallest leaks without the need for trace gases.

The principle is based on one of the oldest and most intuitive methods of leak detection: the bubble test in a water bath. The test package is placed in the chamber filled with water and pressed underwater by means of a downholder. With the aid of compressed air and a venturi nozzle, a vacuum is generated in the air space above the water level. The package immersed in water inflates.

Testing time takes just a few seconds. At the location of a leak, air or filling gas escapes as a visible stream of bubbles. This is particularly important in order to identify at which point in the packaging process an error may have occurred such as a material defect or sealing problem.

LEAK-MASTER EASY is recommended for altitude simulation test. For ease of checking the stability of a package, it can also be tested in the dry chamber.

LEAK-MASTER PRO: Leak detection system for packages containing CO2

Modified atmosphere packages normally contain CO2 as part of the protective atmosphere. LEAK-MASTER PRO uses this CO2 as a trace gas.

Packages can be tested for leaks directly after the packaging process. A settable vacuum is produced inside the chamber. CO2 escapes through the smallest leaks, resulting in pressure differences between the tested package and the testing chamber. The CO2 concentration within the chamber rises. The highly sensitive sensor reacts and detects even the smallest leaks.

Using this method ensures that the product remains entirely undamaged and dry after testing. LEAK-MASTER PRO checks leak tightness of packages to avoid any quality risks and meets the requirements of the HACCP concept.

With a special WITT control software package the measurement documentation can be integrated into the overall quality system. All results, including date, time, product details and username can additionally be sent to MS-Excel.

For data transfer WITT is offering the industrial standard Ethernet. Via this interface, LEAK-MASTERR PRO can be connected to the company network.

LEAK-MASTER MAPMAX: Inline micro leak detection system for packages containing CO2

LEAK-MASTER MAPMAX features non-destructive detection of even the smallest leaks using CO2 as trace gas, a 100 % testing method connected directly to the packaging process. As a result, not a single leaking package gets to the customer.

LEAK-MASTER MAPMAX places the packages or shipping cases in the test chamber. A settable vacuum is produced, resulting in pressure differences between the tested package and the testing chamber.

CO2 escapes through the smallest leaks and the CO2 concentration within the chamber rises. This is detected by a sensor, which allows a resolution of 1ppm.

After each test cycle the chamber is flushed with air and the tested package is forwarded to following systems. If a leak has been detected, several potential free contacts are available for communication with other equipment, which could trigger an alarm or a pusher to sort out a faulty package.

Important facts for the achievable cycle time are the CO2 concentration within the package, the leak size, chamber size and environmental conditions.