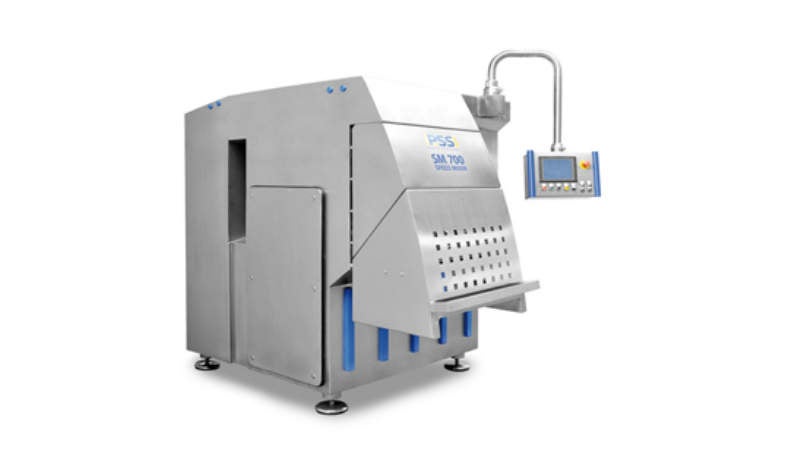

PSS Speed Mixers (SM) are designed for food industry operations for the fast mixing of any kind of product. PSS SMs ensure even and gentle mixing regardless of product structure.

The mixers achieve the best mixing times thanks to its special design. The product is mixed up by maximally overlapping paddles in an almost square, two-level hopper.

Rotating overlapping paddles gently move the product in every direction to deliver the desired final structure. The clearance between the paddles and the hopper is minimal so that there is no compression or squashing of product.

PSS SMs also optimise fast emptying because of the two–level hopper, minimise final product residue and thereby significantly reduce operating time between batches, and can eliminate cross contamination, too.

Options

- Dust lid without sealing

- Grid cap

- Cover plate with sealing

- Weighing system on frame

- Temperature sensor

- Cooling system of top injection N2

- Cooling system of top injection CO2

- Cooling system of bottom injection CO2

- Steam injection system

- Water dosing system

- Double jacket

- Isolation

- Mirror – effect polished hopper and paddles

- Inspection platform

- Remote access via internet

- Frequency inverter (SM 500)