Moxon Industries Manufacturing Equipment Components for Food Processing Plants

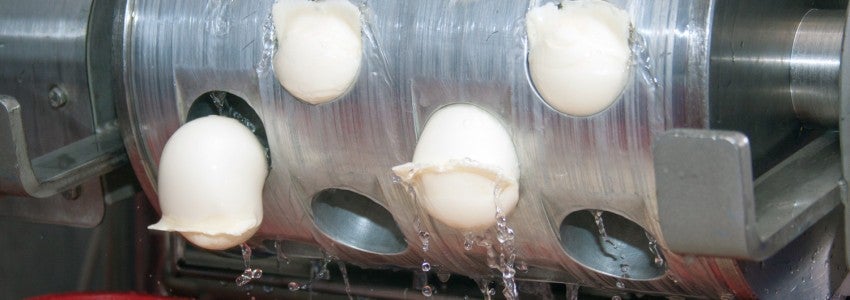

Moxon Industries designs, manufactures and reclaims a wide range of food processing equipment. Its primary customer groups are those who are in the business of processing, refining, handling, manufacturing food products.

The company’s high-precision components and production lines increase the speed and efficiency of food production, as well as reduce bottlenecks. New equipment is designed to be fully integrated into existing infrastructure.

Moxon offers machine engineering and element analysis services for plant upgrades, refurbishments and repairs, as well as designs new facility production lines.

Design services for food processing facilities

Moxon provides project consulting and design services to food manufacturers. Its project managers work closely with clients to develop ideas for whole plants and upgrades.

The company’s engineering division has more than 200 years’ experience creating customised food processing equipment, providing support from initial concept development to the design, trial testing and validation phases.

Components and machinery are manufactured from food-grade stainless steel and plastics, as well as feature customised mechanical and electrical layouts.

Moxon creates prototypes utilising 3D modelling and laser sintering to ensure new components / systems will fit into current processing lines.

CNC manufacturing of food production machinery components

Moxon uses its extensive network of machining centres and metalwork facilities to create high-performance food manufacturing equipment in different shapes and sizes. Its computer numerical control (CNC) machinists produce highly precise components such as splines, gears, leadscrews, shafts and bushes. The company utilises automatic bar-feeding equipment to support its CNC machinery in achieving increased production speeds for high-value food processing components.

The company also supports new product development initiatives by partnering with its clients in the development and manufacture extrusion dies and tooling.

In addition, the organisation has in-house waterjet cutting facilities to support the manufacture precision componentry from stainless steel through to food-grade plastics.

Sheetmetal and fabrication services for food processing plants

Moxon’s sheetmetal and fabrication services complement its tool-making and machining capabilities. The company specialises in the design, manufacture and refurbishment of special purpose machinery used in the food processing industry such as:

- Screw extruders

- Mixers

- Barrels

- Process line / conveyors

Moxon has qualified personnel, processes and procedures enabling compliance to Australian and international welding standards.

Project management services for food processing plant sites

Moxon’s project management services support a wide range of facility capital expenditure upgrades, planned maintenance programmes and component overhaul initiatives through to supporting the development of new products.

The company’s project managers work closely with clients to ensure requirements are met in stages, covering concept design through to testing, commissioning and production.

Moxon consistently integrates engineering, procurement and manufacturing activities to deliver projects within a specified timeframe and budget.

About Moxon Industries

Established in 2001, Moxon Industries is an engineering services provider that offers services for design, project management, special purpose machinery, toolmaking, fabrication, low and high-volume CNC machining.

The company is based in Sydney, Australia, and managed by owner Sam Matandos, along with an experienced team of professionals. All tradesmen are highly qualified and extremely passionate about manufacturing. Moxon has a 3,000m² state-of-the-art facility. It consists of more than 200 machines, including some of the latest CNC machine technology.

Being a ISO 9001 Quality certified organisation, Moxon can provide value to its customers by offering a one-stop service, which allows its customers to be at ease that they are dealing with a professional and competent supplier.

Depending on the size of the project, Moxon has an authorised supply chain of manufacturers overseas that can deliver larger projects in shorter timeframes. While Moxon is proud to be an Australian manufacturer, it must also consider alternative options to ensure its customers’ needs and expectations are met.

Moxon has an excellent reputation within the food industry and can provide project references on request.

Over and above being a key supplier to Australia’s food industry, Moxon provides innovative solutions for other industries, including pharmaceutical, nuclear/medical science and healthcare industry.