SteriBeam Systems Systems for Non-Invasive Sterilization with Intense Pulsed Light UV or Pulsed Electrical Fields

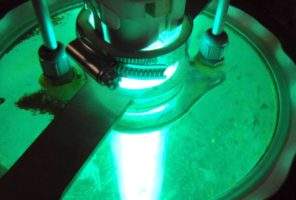

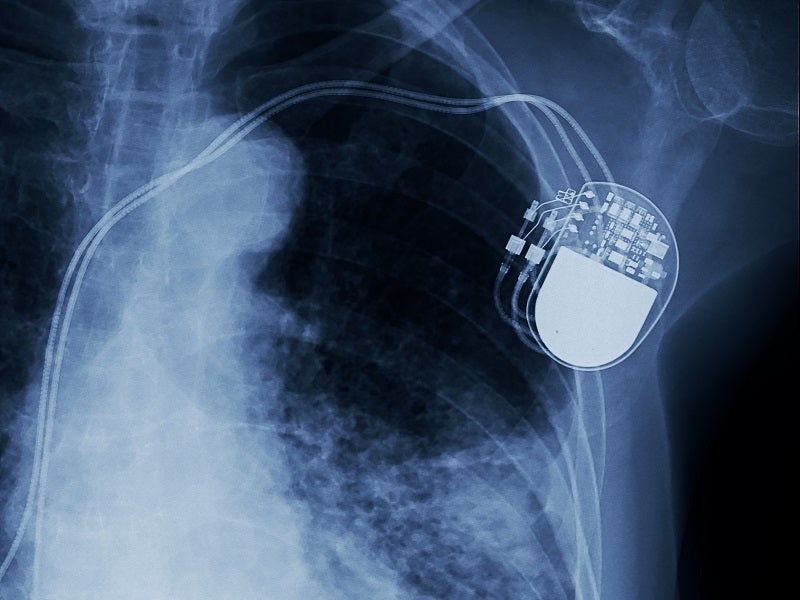

SteriBeam provides advanced pulsed light (UV), continuous UVC light and pulsed electrical field (PEF) systems for non-invasive sterilization or sanitation for production and R&D in the food industry.

Pulsed light UV system benefits for food production

SteriBeam offers customization for cups, jars, lids, small or large packaging and some foodstuffs before or after packaging in UV transparent foils.

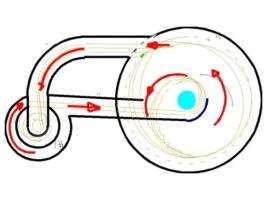

The PEF systems are for sanitation of liquid foods and for non-invasive PEF assisted extraction of juices and colors from vegetative cells.

The advantages of SteriBeam sanitation and sterilization systems include:

- In-line sanitation for up to four logs (99.99%) reduction of common spores and six logs reduction of common bacteria in one second to a few seconds with UV-C lamps

- In-line sterilization for up to six logs (99.9999%) reduction of all micro-organisms, which is also UV resistant, in a few seconds per a pack by pulsed light UV tunnels or R&D systems

- Pulsed UV light lamps emit between 15% and 35% of a broad UVC light, the highest in the industry, and is responsible for cost-effective deactivation of micro-organisms

- Keeps nutrient properties of some treated foods stuffs

- Keeps packaging undamaged

- Competitive and low electrical costs per sterilized item

- Higher safety levels as the system does not generate harmful byproducts , ozone or mercury vapors and no EMC disturbance

- Does not require labeling since it is not radiation, heat or chemical treatment

- Both types of these technologies are quite known and are recommended by the FDA

- Full range of customized production UV or PEF tunnels and R&D systems, semi and fully automated.

Additional options are available including:

- Sterile gates between two clean production rooms of different classification (e.g. between A and B)

- PEF assisted extraction of juices or natural colors from vegetative cells by increasing the yield and keeping all original properties in place

UV tunnels for sterilization of food packaging

SteriBeam can help to find UVC components for other systems, if it is not listed, using correlations between pulse duration and energy plus lamp geometry.

SteriBeam offers customized UV tunnels to sanitize or sterilize:

- External and internal surfaces of packaging, cups and lids

- Products which require the full 360° illumination

- Products which require six logs of sterilization, including UV-resistant spores and fungi

- Product flow of up to 36,0000/hr (ten/sec, depending on size and log requirements)

- Some open foods and foods packaged in UV transparent packaging (e.g. Topas foils)

Bench-top pulsed light UV systems

SteriBeam’s bench-top R&D systems have been successfully used worldwide due its broad parameters, labs and competitive pricing including customization to research goals.

The range of advantages includes:

- Product exposure from 180° to 360°

- Pulse energies that are available from 100J to 1,000J

- UVC fluxes to the product of up to 2J/cm²/pulse

- UVC power during pulse of up to x10 kw/cm²

- Pulse repetition rates for fully automatic: 1Hz-5Hz

- Changeable reflectors in three sizes with adjustable sample shelves

- IR and visible light filters

- Sensors to record UV and current pulses with PC scope

SteriBeam specializes in pilot bench-top PEF sanitation and juice extraction systems, which offers various benefits including:

- Pulsed shape: square pulse with timed durations of two µ seconds – 50µ seconds, 5% flat, fronts <one µs, tails <ten µs

- Pulse polarity: positive or optional bi-polar square pulsing

- Pulse energies to set: 5J- 50J

- Pulse repetition rates of 1Hz-100Hz

- Maximum power output of up to 3kw

- Pulse bursts: 1-1,000 pulses / exposure, or timed continuous pulsing

- Processing chamber for liquids and a chamber for solid or shred products

- Versatile fully automated and low budget semi-automatic with the same pulse parameters

UV systems for shred or powdered food products

UV systems are available for disinfection or for a controllable photosynthesis of nutrients. It works by circulating shred or powdered products around a UV lamp or in a flow-through production type system of a proprietary design at up to 1,000 kg/h.

Important note: Any claim of pulsed light ability to sterilize has to supported by presenting the UVC part (220nm-280nm) in the pulsed light. Otherwise, unaware customers falsely believe that ‘any sun like spectrum of a flash lamp’ can sterilize, which is wrong.

Since 2001, it was proven that only the UVC component in pulsed light is responsible for almost 95% deactivation of micro-organisms.

When the UVC part is below 10%-12% or 3%-5% in pulsed light systems, it is less expensive to sanitize with continuous UVC amalgam lamps, which are just as safe as flash lamps are.

Note: SteriBeam is looking for an industrial partner-investor to expand its operations.

Please see our website for more information.

Products and Services

Video

Related Projects

Press Release

Disinfecting inner surfaces of jars on conveyer lines with UVC light at high production rates is the preferred choice of non-invasive, clean disinfection. This production step is necessary to assure the safety of filling jars with product and then cupping them.

Read moreSteriBeam Systems has developed a pilot UVC system for the sanitation of spices and powders in a vortex flow.

Read moreThe major parameters of the SteriPulse RS 3000 XL by Xenon Corp have been compared with the parameters of XeMaticA-2LFA, the fully automatic two lamp system with an interactive LCD display, and with the basic one lamp semi-automatic XeMaticA-SA-1L.

Read moreMajor parameters of the floor-standing R&D PEF system type DIL/ELCRACK-5kw have been compared with the respective parameters of three SteriBeam bench-top R&D PEF systems: the fully automatic system with an interactive LCD display, the semi-automatic-1 and the basic semi-automatic-2.

Read moreNew SteriBeam White Paper Discusses Pulsed vs. Continuous UV for In-Line Sterilisation or Sanitation

For high-speed in-line sanitation of cups, lids, etc. (max to 99.99%, 3,000 cups/h) the optimal UV equipment is U-shaped amalgam low-pressure mercury vapour lamps.

Read moreFor R&D in non-invasive sterilization of liquid foods, juices and pharmaceutical liquid products, as well as for extraction of nutrients from vegetative cells, SteriBeam has developed novel bench-top semi-automatic and fully automatic PEF (pulsed electrical field) systems.

Read moreSteriBeam Systems, based in Kehl, Germany, has introduced fully automated in-line pulsed UV sterilisation tunnels for pilot and production lines.

Read moreSteriBeam has developed a pilot R&D PUV system for reducing bio-burden in powdered and shredded products.

Read moreVitamin D2 enrichment with SteriBeam's pulsed UVB source has been conducted on two types of fresh mushrooms: white champignons and oysters.

Read moreBacillus Subtilis spores have been inoculated over internal surfaces of large water bottling cups from Nestle Shanghai Source.

Read moreRegional Offices

Gottlieb-Fecht Str 32

Kehl am Rhein (by Strasbourg)

D-77694

Germany