METTLER TOLEDO Machine Vision Inspection Systems for Food Packaging

METTLER TOLEDO provides advanced software to optimize label and packaging inspection in the food and beverage industries.

Designed to improve manufacturing efficiency and product quality, the company’s machines help ensure customer safety by quickly identifying defective products for removal from the production line.

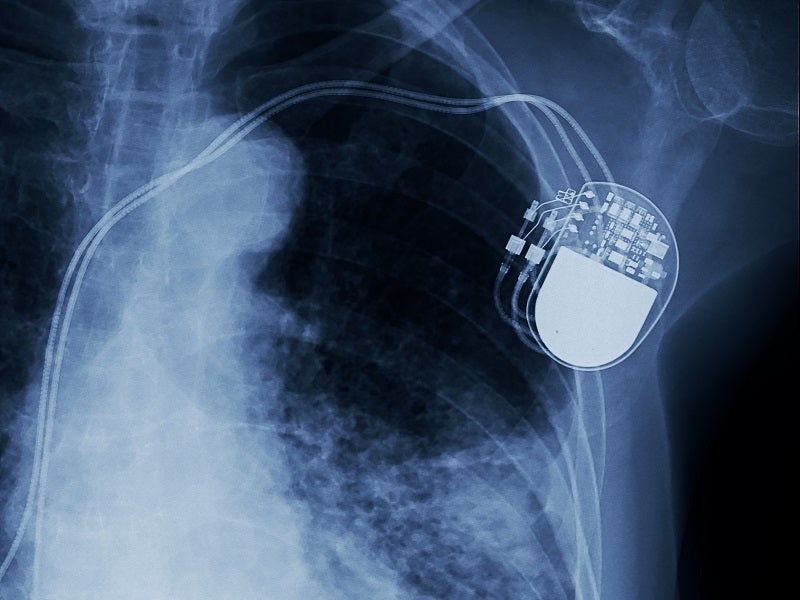

METTLER TOLEDO’s product inspection division comprises CI-Vision, PCE, Hi-Speed, and Safeline technologies, which provide high-quality inspection equipment for serialization, checkweighing, metal detection, and X-ray inspection applications.

Vision inspection solutions to mitigate product recall

METTLER TOLEDO’s inspection systems help mitigate product recalls and reduce rework of the production line. The systems monitor and manage label and package integrity, minimize costs, and optimize product changeover.

Each label inspection function increases customer safety by preventing mislabeled products from leaving the production floor. Each label is carefully inspected and verified to ensure it contains the correct allergen declaration. Inspection of lot codes or barcodes also helps to ensure traceability in the event of a recall due to contamination.

Custom parameter inspection

METTLER TOLEDO’s powerful CIVCore software has a flexible and intuitive user interface, with a large array of tools designed to help eliminate production errors.

It is able to inspect many different parameters, ranging from cap integrity to label accuracy and package inspections.

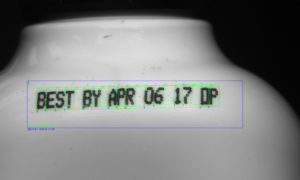

It also has the capability to detect and inspect inkjet printed labels with the Dot Print Tool, reassuring manufacturers that the final printed packaging or label clearly shows all the required information to meet international regulatory requirements.

Increase operational efficiency in food production plants

Using advanced reporting features, statistical analysis, and integrated connectivity, clients can efficiently manage production lines.

METTLER TOLEDO’s qualified service team provides proactive maintenance to ensure minimal downtime to production.

Comprehensive project management, set-up, and serviceability

METTLER TOLEDO’s team surveys a client’s site and evaluates product requirements to ensure no details are missed prior to installation.

Providing this level of detail in set-up ensures the systems are installed on-time and on-budget.

With a global presence in 39 countries, METTLER TOLEDO provides expert troubleshooting to solve issues. The company is known for its service and customer support.

Products and Services

V2630 Flexible Vision Inspection System

Mislabeled or damaged packaging lead to a huge profit loss annually. But in serious cases, they can negatively affect a brand's reputation or cause health problems for customers with allergies.

V2410 Mosaic-Paneled for the Inspection of Un-oriented Products

Round un-oriented packaged goods are a challenge for vision inspection systems because there is no way to be certain the elements of inspection will be facing the cameras when they come through the system.

White Papers

Track & Trace in Agrochemicals

From the first moment that primitive man noticed he could bury tiny things in the ground and wait for them to turn into larger things, which he could eat, technology has played an important role in agriculture.

Beverage Quality Inspection – Ensuring Perfect Product Presentation

The beverage market is one of the largest and most competitive markets in the world. Competition gets even higher when discussing soft drinks, with a growing trend in bottled water. This has presented a problem for beverage manufacturers, as it is easy to create a unique soft drink that finds a niche audience, but finding the niche of people interested in your brand is a more difficult task.

Related Projects

Press Release

By choosing the V2410 Mosaic, companies in the food and cosmetics industries are opting for a powerful, space-saving 360° inspection solution for visual packaging and label control.

Read moreMETTLER TOLEDO has announced the release of the latest version of its CIVCore software, featuring the Dot Print tool, the winner of the WestPack Innovation Award 2017.

Read moreRegional Offices

2640 White Oak Circle, Suite A

Aurora, IL 60502

United States of America